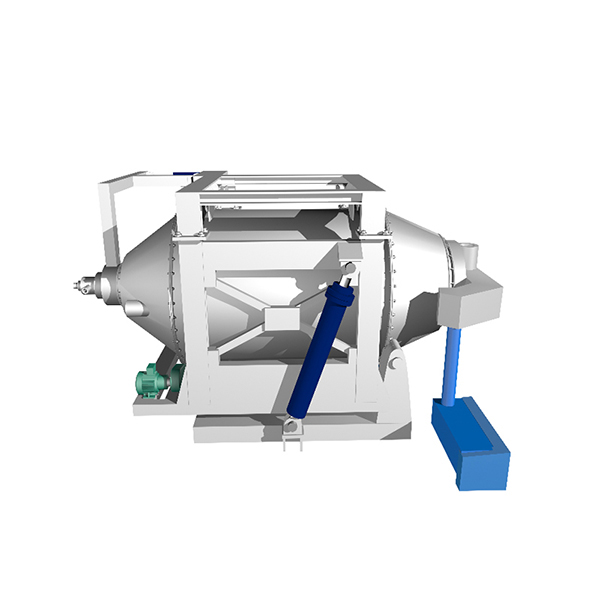

The antimony rotary furnace is a highly efficient, environmentally friendly, high-temperature processing equipment designed specifically for the antimony smelting industry. It is primarily used to extract and refine metallic antimony from antimony concentrate, antimony-containing waste, or antimony oxide (antimony trioxide). Its unique rotary design ensures full and uniform contact between the material, the heat source, and the reaction gases, significantly improving reaction efficiency and metal recovery while effectively reducing energy consumption and environmental pollution.

Furnace system

The furnace drum utilizes a multi-layer composite structure, lined with high-grade refractory materials and housed in a high-quality boiler steel shell. The drive unit, consisting of a motor, reducer, and gear transmission system, drives the furnace body to rotate smoothly at an adjustable speed of 0.5 to 2.0 RPM. The supporting structure utilizes rollers and rollers, providing strong load-bearing capacity, low friction, and stable operation.

Heating system

Fuel options include natural gas and diesel, tailored to customer needs. The burner is highly efficient, low-nitrogen, and energy-efficient, with precise air-fuel ratio control and adjustable flame and temperature. High-performance insulation material is applied to the exterior of the furnace to minimize heat dissipation and improve thermal efficiency.

Feeding and discharging system

The feeding end is equipped with a sealed feeding bin and feeder to ensure uniform feeding and prevent gas leakage. The discharging end is equipped with a slag outlet and an antimony liquid outlet to achieve slag and antimony separation, and the discharging port is sealed to prevent air infiltration.

Flue gas and environmental protection system

A fume hood is installed at the feed end to collect flue gas, and a waste heat boiler can be optionally installed to recover heat energy. A high-efficiency dust collector is connected to the back end to capture dust and recover the product. Desulfurization and denitrification equipment can be installed to ensure environmental protection standards.

Automation control system

With PLC or DCS as the control core, it monitors and automatically adjusts temperature, speed, pressure, etc. in real time. Key parameters are displayed, recorded and alarmed in the central control room, realizing "one-button" operation and fault diagnosis.

This antimony rotary furnace is the culmination of modern antimony smelting technology. Combining high efficiency, energy conservation, environmental protection, and intelligence, it is the preferred equipment for replacing traditional, outdated processes and promoting the upgrading of the antimony smelting industry. We can provide a complete solution from design and manufacturing to installation and commissioning, tailored to the customer's specific raw materials, production capacity, and site conditions.